close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-23 Origin: Site

In industries like mining, construction, and agriculture, choosing the right screening media is crucial for efficiency. Rubber screen plates offer a durable and versatile solution, surpassing traditional materials such as metal or polyurethane. In this article, we’ll explore the advantages of rubber screen plates and their various applications, highlighting how they improve operations and reduce costs.

Rubber screen panels are designed using high-quality rubber materials, often reinforced with fabrics like polyester or steel wire. The elasticity of rubber gives these panels their key advantages: impact resistance, flexibility, and noise reduction. They absorb vibrations and withstand harsh conditions, making them ideal for handling large or abrasive materials in industries such as mining and construction.

Rubber screens can be molded into various shapes and sizes to accommodate different materials and operational needs. These panels are constructed to withstand heavy loads and reduce the wear that occurs when dealing with challenging materials, including demolition debris, minerals, or other coarse aggregates.

Rubber screen panels come in different designs to suit specific industrial requirements. The two primary types are:

● Modular Designs: These panels are made from smaller, individual sections that can be easily replaced when damaged. This modularity allows for quick maintenance and customization of the screen deck.

● Non-Modular Designs: These are typically used in more rigid setups where the panels are fixed in place, offering a sturdy solution for environments where regular maintenance is less frequent.

Specific variations of rubber screens include heavy-duty versions for tougher applications, as well as lightweight designs suited for less demanding environments.

Rubber screen panels are available in standard sizes, often ranging from 305x610 mm to custom dimensions based on operational needs. They are adaptable to a variety of equipment, including vibrating screens and other modular setups. Depending on the type of screening, panels can be tailored to accommodate small or large particles.

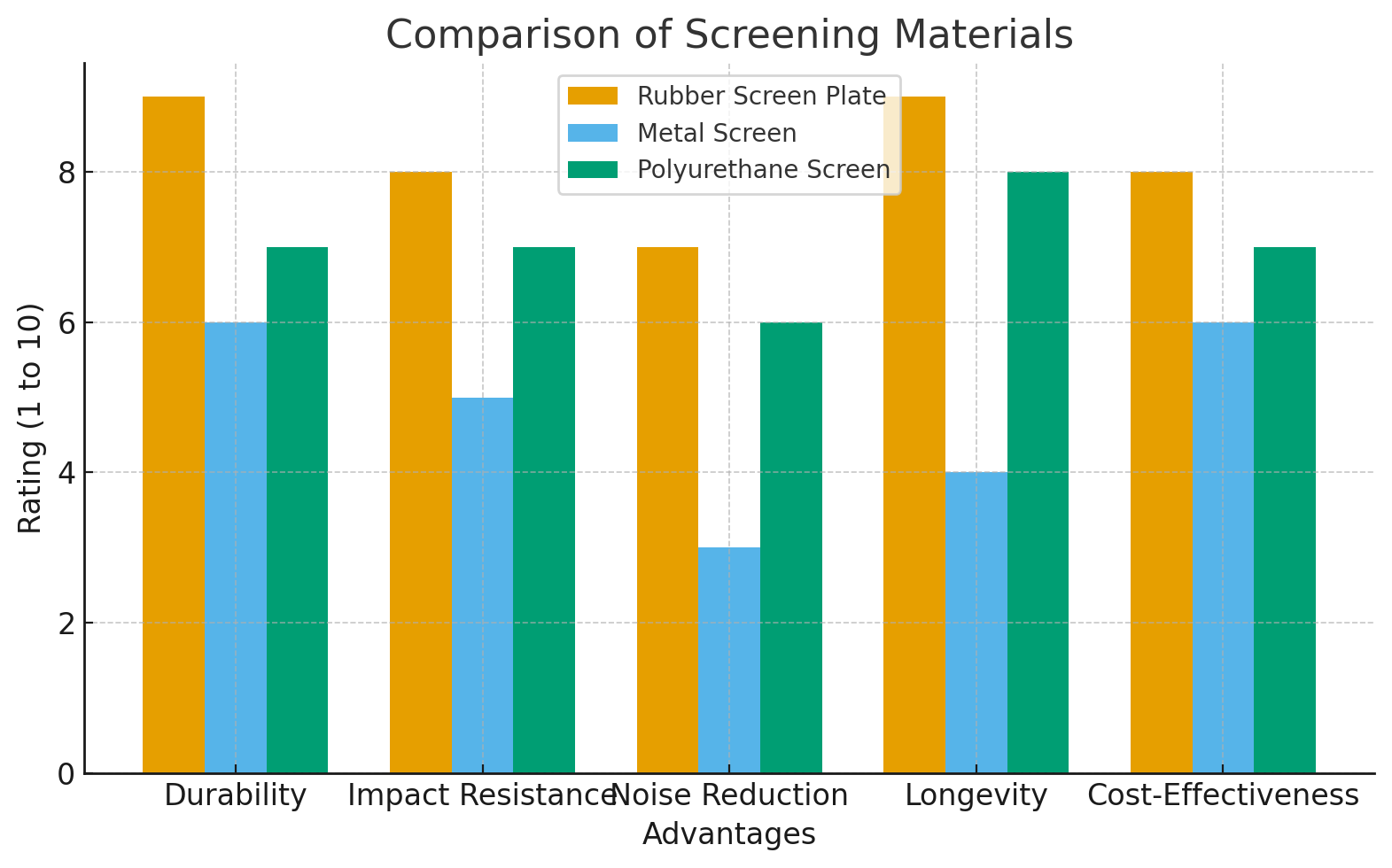

Rubber screen panels are known for their durability, outlasting many traditional materials, including metal and polyurethane. They have a higher wear resistance, making them ideal for continuous use in demanding environments. The robust nature of rubber allows it to resist both physical impact and abrasion, extending the life of the screening system.

Rubber panels have a significant advantage over metal screens, especially when it comes to impact resistance and noise reduction. While polyurethane screens also offer durability, rubber typically performs better in environments that involve heavier, sharp-edged materials.

Noise reduction is a crucial factor in many industrial operations, especially where workers’ health and safety are a concern. Rubber screens naturally absorb vibrations, reducing noise levels significantly compared to metal-based screening systems. This creates a quieter working environment, which can extend the amount of time workers can safely operate in the area without risking hearing damage.

Rubber’s inherent flexibility makes it well-suited to handle heavy, sharp, or irregular materials, such as rocks and construction debris. This ability to absorb impact helps to maintain the integrity of the screening system, preventing damage to both the screens and the surrounding machinery. Rubber screens also adapt well to a variety of materials, whether wet or dry, without losing effectiveness.

Although rubber screen panels may have a higher upfront cost compared to traditional materials, their longevity and durability make them a cost-effective investment over time. The longer lifespan, reduced maintenance needs, and fewer replacements lower the overall cost of ownership. These factors make rubber screen panels a financially savvy choice for businesses looking to improve operational efficiency while reducing long-term expenses.

In the mining industry, rubber screen panels play a critical role in mineral processing, coal washing, and ore separation. These panels handle abrasive and coarse materials such as sand, gravel, and coal with ease. The impact resistance of rubber makes it an excellent choice for processing heavy, sharp-edged materials commonly found in mines.

Rubber’s flexibility allows for better throughput in screening operations, as it ensures that material moves efficiently through the system, reducing blockages or inefficient separation.

Rubber screen panels are commonly used in construction and demolition sites to process large debris, including concrete, steel, and other heavy materials. Their ability to absorb impacts and resist wear makes them ideal for these environments. Rubber screens can handle the rough treatment often encountered in these operations, offering extended service life compared to other types of screen media.

In recycling and waste management, rubber screen panels are used to separate recyclable materials and reduce waste. They are effective at sorting mixed materials while preventing clogging. Rubber screens also contribute to better waste handling in facilities processing everything from plastics to metals, enhancing the overall sorting process.

Rubber screen panels are also used in the food and agricultural industries for operations that require a high level of hygiene and noise reduction. Rubber screens are easy to clean and maintain, making them a great choice for food processing plants. They are used in seed processing, grain sorting, and other agricultural applications where noise reduction and material integrity are important.

Rubber screen panels offer several advantages over traditional metal screens. First, they are more flexible and better at absorbing impacts, which makes them ideal for handling heavy or irregular materials. Rubber screens also have better noise-reducing properties, which is essential for worker safety. Additionally, rubber typically lasts longer than metal screens, especially in abrasive environments.

Unlike metal, which can corrode or degrade under wet conditions, rubber maintains its integrity when exposed to moisture. This makes rubber panels particularly effective in industries like coal washing or mineral processing, where wet conditions are common.

Rubber and polyurethane screen panels are often compared, as both materials offer excellent durability and wear resistance. However, rubber is typically more flexible, making it ideal for applications where impact resistance is crucial. Polyurethane, on the other hand, tends to offer slightly better abrasion resistance and is often more rigid. The choice between rubber and polyurethane depends on the specific demands of the operation—rubber excels in flexible, impact-heavy environments, while polyurethane is better suited for more abrasive materials.

Rubber’s adaptability is especially beneficial in modular screening systems. These systems often require components that can be easily replaced or reconfigured. Rubber screen panels are an excellent fit because they can be designed in modular sections that are quick to install or replace. This modularity enhances operational efficiency and minimizes downtime, as worn-out panels can be replaced without disturbing the entire system.

When selecting rubber screen panels, it’s important to consider the specific characteristics of the material being processed. Rubber panels are most effective for materials that are abrasive, large, or sharp. Matching the material to the right screen helps optimize performance and lifespan.

Rubber screens perform well in a variety of environmental conditions. However, factors like temperature, moisture, and impact must be considered. Rubber panels thrive in environments with heavy impact or abrasive materials, but extreme temperatures might affect their performance. It’s essential to select rubber screens that are compatible with the operational environment.

While rubber screen panels might require a higher initial investment, the long-term cost savings are significant. Their durability and longer service life mean fewer replacements and reduced downtime, leading to lower maintenance costs and a higher return on investment.

For industries where noise levels are regulated or worker health is a concern, rubber screens are an ideal choice due to their superior noise-reducing capabilities. This makes them particularly beneficial in sectors like mining, construction, and recycling, where high noise levels can be a challenge.

Maintaining rubber screen panels is relatively simple compared to other materials. Regular cleaning to remove debris, inspection for wear, and ensuring the panels are securely fastened can significantly extend their lifespan. It's essential to check for any cracks, tears, or signs of excessive wear, especially in high-impact areas.

Over time, rubber screens may show signs of wear or reduced performance. Indicators that replacement is necessary include visible cracks, significant deformation, or a decrease in screening efficiency. Early replacement can prevent downtime and ensure that the screening process remains efficient.

Rubber screen panels offer durability, impact resistance, and noise reduction, making them ideal for industries like mining, construction, recycling, and agriculture. Their flexibility and longevity help improve operational efficiency, reduce maintenance costs, and enhance worker safety. Kminda's rubber screen plates provide significant value, offering cost-effective, high-performance solutions for businesses aiming to optimize their operations and productivity.

A: Rubber screen plates are designed for industries that require durable, impact-resistant screening solutions. They are ideal for mining, construction, recycling, and agriculture, handling a variety of materials efficiently.

A: Rubber screen plates offer better impact resistance, flexibility, and noise reduction compared to metal screens. They also have a longer lifespan and require less maintenance, making them a cost-effective choice.

A: Rubber screen plates enhance operational efficiency by reducing downtime and maintenance costs. Their flexibility and durability make them ideal for harsh environments where other materials might fail.

A: Rubber screen plates are known for their exceptional longevity. They outperform many traditional materials, providing extended service life even under demanding conditions.

A: Yes, Rubber screen plates are available in various sizes and designs, allowing for customization to meet the specific needs of industries like mining, construction, and recycling.