close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

Wet screening plays a critical role in industries like mining, construction, and recycling. But handling wet materials often leads to clogging and inefficiency. Rubber screen plates offer a powerful solution, excelling in such environments.

In this article, we will explore the performance of rubber screen plates in wet screening, emphasizing their durability, cost-effectiveness, and efficiency in improving operations.

Wet screening is the process of separating materials using water or other liquids to reduce clumping and improve separation efficiency. It is commonly used in industries that process fine, moist, or sticky materials, such as coal preparation, aggregate processing, and mineral recovery. Wet screening allows for better material classification and helps to prevent the clogging of screens, which is often seen in dry screening processes.

Wet screening is essential for improving the quality and purity of materials, ensuring that they are properly separated and ready for further processing. It enhances product quality, increases throughput, and reduces the chances of material contamination.

In industries like mining and recycling, wet screening is used to remove impurities from raw materials and enhance the efficiency of subsequent processes. For example, in coal washing, wet screening ensures that fine coal particles are separated effectively, improving the quality of the final product. Similarly, in recycling, wet screening helps separate different materials, optimizing the recycling process and ensuring that valuable materials are recovered.

Wet screening also plays a vital role in environmental protection, as it helps in handling materials more sustainably by reducing waste and improving material recovery rates.

Rubber screen plates stand out due to their ability to handle wet and sticky materials efficiently. Their elasticity allows them to conform to the shape of the material, reducing the chances of clogging and ensuring a smoother flow of materials. In wet screening, where moisture can bind particles together, rubber’s anti-clogging properties help maintain efficient screening without material blockages. This characteristic makes rubber screen plates ideal for processing fine, wet coal, sand, and other materials prone to clumping.

Rubber is naturally resistant to wear and tear caused by abrasive materials, making rubber screen plates highly durable in wet conditions. Unlike metal or woven wire screens, rubber plates can withstand the constant impact of wet materials without significant degradation. This results in a longer service life for the screen plates, which reduces the need for frequent replacements and minimizes downtime. The high wear resistance of rubber in wet environments ensures that the screening process remains efficient over time.

While rubber screen plates may have a higher upfront cost compared to metal or polyurethane options, they prove to be more cost-effective in the long run. The extended lifespan of rubber plates, coupled with their resistance to clogging and wear, reduces maintenance costs and the need for frequent replacements. Businesses can save significantly on operational costs as rubber screen plates provide better overall performance, reducing downtime and maintenance-related expenses.

Rubber screen plates excel in handling materials with varying moisture content. Whether the material is mildly moist or fully saturated, rubber plates provide reliable performance, preventing clogging and maintaining consistent screening efficiency. In industries like mining and coal preparation, where materials often contain high moisture levels, rubber’s flexibility and anti-clogging capabilities ensure smooth operation without material buildup. This adaptability makes rubber a versatile choice for many wet screening applications.

Rubber screen plates are particularly effective when dealing with high-viscosity materials, such as thick slurries or sticky coal slimes. The material's viscosity can cause other screen types to become clogged, reducing screening efficiency. However, rubber’s elasticity allows it to handle such materials effectively, preventing clogging and ensuring proper separation. This makes rubber screen plates the ideal choice for industries processing materials that contain fine particles or slurry-like substances.

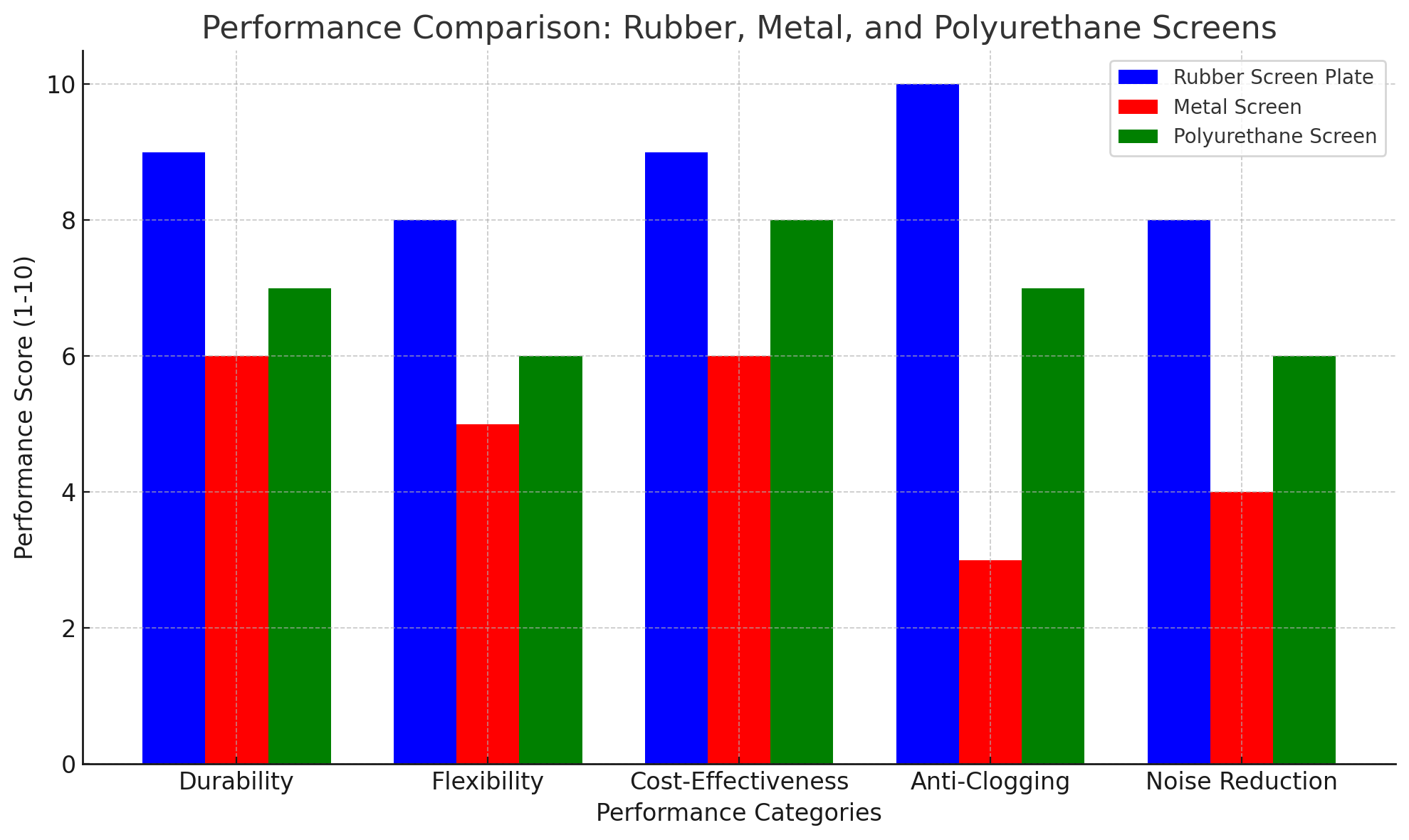

When comparing rubber screen plates to metal screens, rubber offers several advantages. Rubber’s flexibility allows it to absorb impact and vibrations, making it ideal for handling large or abrasive materials. It also offers superior noise reduction, which is an important factor in industrial environments where worker health is a concern. Metal screens, on the other hand, can be prone to corrosion in wet conditions and may need frequent maintenance. Rubber’s natural resistance to corrosion, combined with its durability and impact resistance, gives it a distinct advantage over metal.

Polyurethane screens are another popular choice for wet screening, but rubber screen plates often outperform them in certain applications. While polyurethane is durable and wear-resistant, rubber provides superior flexibility, allowing it to handle sticky and wet materials more effectively. Rubber also tends to perform better in high-impact environments, making it the better option for industries dealing with coarse materials or materials with sharp edges. Additionally, rubber’s cost-effectiveness in the long term, due to its extended lifespan and lower maintenance requirements, gives it a competitive edge over polyurethane in many cases.

Rubber screen plates come in both modular and solid designs, each offering specific advantages depending on the application. Modular rubber screens allow for quick replacement of individual sections, reducing downtime and simplifying maintenance. They are ideal for operations that require flexibility and easy replacement of worn-out parts. On the other hand, solid rubber screens provide a more rigid solution and are typically used in environments where long-lasting performance and high durability are crucial. Both types of rubber screens offer superior performance in wet screening compared to other materials.

In the mining industry, especially in coal preparation plants, rubber screen plates are used extensively in wet screening to separate fine coal particles from larger debris. Case studies have shown that rubber screen plates provide superior performance in handling the fine, wet coal slurries that are typical in these applications. By preventing clogging and ensuring better material flow, rubber screens help improve the overall efficiency of the screening process, reducing downtime and maintenance costs.

In sand and aggregate processing, wet screening is essential to separate fine particles from larger ones. Rubber screen plates are particularly effective in these applications due to their resistance to clogging, flexibility, and durability. They provide reliable performance in environments where moisture levels can vary significantly, ensuring consistent material separation and improved product quality.

Rubber screen plates also play a vital role in the recycling and waste management industries, where they help in efficiently separating recyclable materials. The flexibility and anti-clogging properties of rubber make it ideal for handling mixed and wet waste, preventing material blockages that could reduce processing efficiency. Rubber screen plates help optimize material recovery and improve the overall productivity of recycling plants.

Choosing the right rubber composition for wet screening is essential to ensure optimal performance. Factors such as the abrasiveness of the material, moisture content, and particle size all influence the choice of rubber screen plates. Selecting the right type of rubber ensures better durability and efficiency, particularly in harsh, wet conditions.

Rubber screen plates come in various sizes, aperture configurations, and thicknesses to meet specific screening requirements. Customization options allow businesses to select the ideal screen plate design based on their operational needs. Whether the application involves fine coal or heavy aggregates, customized rubber screen plates can provide the best results in wet screening environments.

Before full-scale implementation, businesses should test rubber screen plates to ensure they meet the performance requirements for their specific applications. Testing can help validate the efficiency of the rubber screen plates under wet screening conditions, ensuring that they handle materials effectively and improve overall process efficiency.

Rubber screen plates provide exceptional performance in wet screening, offering significant advantages in mining, coal preparation, and recycling. Their durability, flexibility, and ability to handle wet and sticky materials make them a cost-effective and reliable choice. By investing in rubber screen plates, businesses can optimize wet screening processes, minimize downtime, and lower maintenance costs.

Kminda offers high-quality rubber screen plates, ensuring optimal performance and efficiency for industries. Integrating these products into your operations can enhance productivity while reducing long-term costs.

A: A Rubber Screen Plate is designed to handle wet, sticky, and abrasive materials in screening applications. It excels in wet screening by preventing clogging and offering durability in challenging conditions.

A: Rubber Screen Plates are highly durable, flexible, and resistant to wet and sticky materials. They reduce maintenance costs and downtime, making them a cost-effective choice for wet screening.

A: Rubber Screen Plates outperform metal screens in wet conditions due to their flexibility, noise reduction, and resistance to corrosion. Rubber plates provide better efficiency and longevity in wet screening environments.

A: Yes, Rubber Screen Plates are cost-effective in the long run. Their durability reduces the frequency of replacements and maintenance, ultimately lowering operational costs.

A: Rubber Screen Plates perform well with high-viscosity materials. Their flexibility and anti-clogging properties help prevent blockages, ensuring smooth material flow and efficient screening.