close

Choose Your Site

Global

Social Media

Introduction

KMD FGC circular vibrating screen uses a motor as a single excitation source to drive the whole screen box to do circular vibration. Supporting the use of KMD independent research and development of flexible polyurethane screen, high screening efficiency, less energy consumption, easy to maintain.

High frequency vibration motor is used in the circular vibrating screen, and the vibration frequency reaches 1500r/min. It has higher processing ability in treating pulp with lower solid content.

The rotary vibrating screen covers an area of small, large unit capacity, low power consumption, small dynamic load. Adopt flexible polyurethane screen with high opening rate independently developed by our company, the average life is more than 6 months, easy to replace spare parts, stable operation and small maintenance.

Circular vibrating screen Feature and Advantage

2.1) Due to the strong vibration of the screen box, the phenomenon of material blocking the screen hole is reduced, so that the screen has higher screening efficiency and productivity.

2.2) Simple structure, convenient disassembling and changing screen surface.

2.3) Less power consumption per ton of material screening.

Rotary vibrating screen listing

| Landsky Model | Decks (Stank) | Length (mm) | Width (mm) | Working Area (Screening) | Power (KW) | Aperture Range (mm) |

| FGC1028 | 1 | 2.8 | 1.0 | 2.8 | 1 x 2,2 | 0.053-4.2 |

| 2FGC1028 | 2 | 2.8 | 1.0 | 5.6 | 2 x 2.8 | 0.053-4.2 |

| FGC1440 | 1 | 4.0 | 1.4 | 5.6 | 1 x 3.4 | 0.5-4.2 |

| 2FGC1440 | 2 | 4.0 | 1.4 | 11.2 | 2 X 3.4 | 0.5-4.2 |

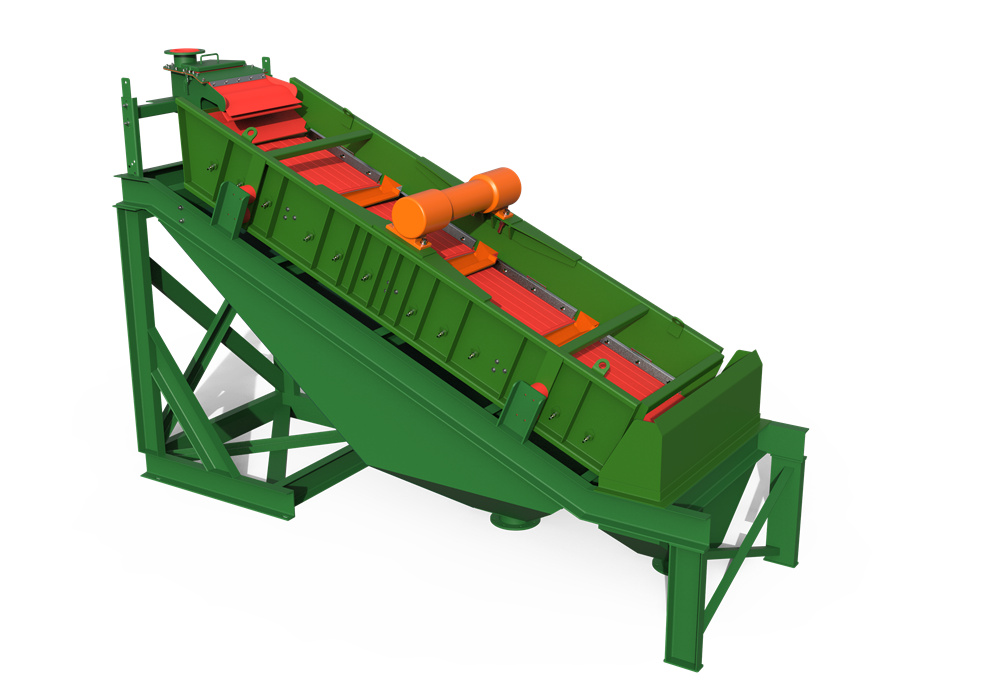

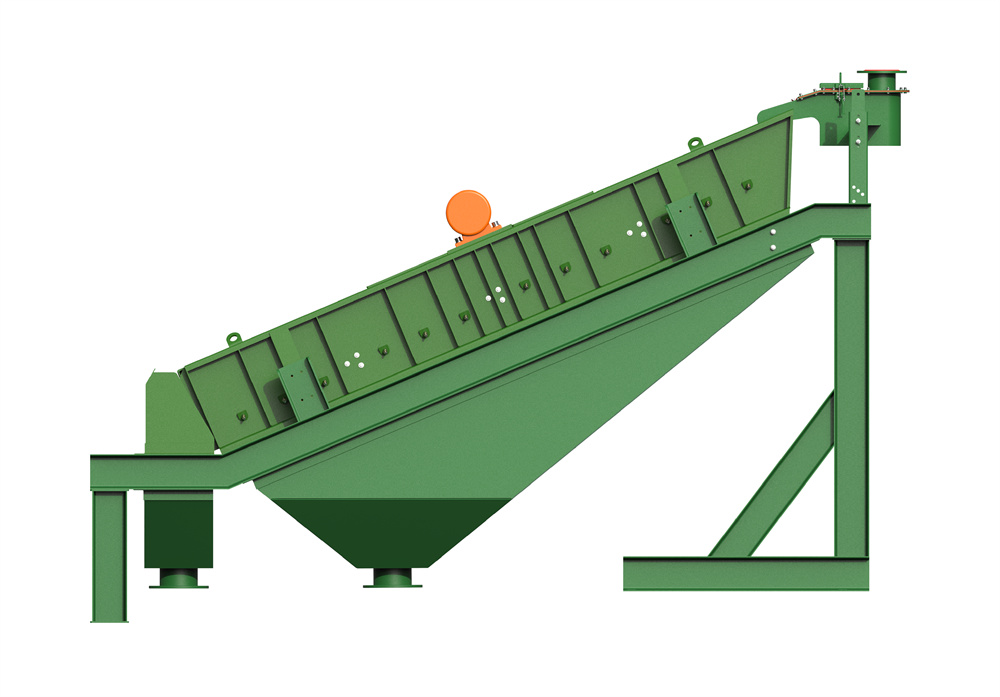

3D Model

|  |

|  |

Application

Circular vibrating screen is widely used in mining, building materials, energy, chemical and other industries of product classification.

OEM

Our company can be customized according to the actual situation of different users, can be a variety of specifications, a variety of vibration mode of the vibrating screen.