close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

Introduction

Banana screen also called equal thickness vibrating screen. KMD banana sieve adopts international advanced design concept, processing technology and testing technology. According to the principle of equal thickness screen surface, the continuous multi-angle screen surface design (usually composed of three Angle, five Angle and seven Angle) is adopted. It has the advantages of high stability, large handling capacity and long service life.

KMD equal thickness screen can handle 2 to 3 times of the traditional vibrating screen per unit area. Equal thickness sizer/screen is widely recognized by users for its large processing capacity, high screening efficiency, stable and reliable performance.

Feature and Advantage

Engineered up to 4.3m in width and 9.7m in length

Using the principle of equal thickness screening design, international advanced screening technology and processing technology;

Screen surface continuous multi-angle design, with high stability, large capacity, long service life and other advantages;

Independent research and development and manufacturing of key core components, stable operation and small maintenance;

Product diversification, there are three types of single deck, double deck and triple deck;

The difference between decks of double screen surface is 1.2m, convenient to replace the screen plate;

The screen plate is made of polyurethane or rubber material, and a variety of holes are selected.

Cloud intelligent monitoring system for vibration parameters (optional);

AH36 ship plate is used for side plate, wear resistant and anti-corrosion paint is used for equipment surface

High throughput per screening area

Excellent sizing efficiency due to rapid stratification of fines

All-bolted construction using locking bolts to ensure structural integrity

Wear-resisting rubber installed to protect the machinery during highly corrosive applications and lower the total cost of ownership

Banana screen listing

| Family | Type | Landsky Model | Decks (Stank) | Working Area (Screening) | Mesh Tipe (mm) | Aperture Range (mm) | Power (kW) |

| LKBB | Banana | LKBB1836 | 1 | 6.48 | Panels (610x610, 305x610, 305x305) | 3-120 | 1 x 18,5 |

| LKBB | Banana | LKBB1848 | 1 | 8.64 | Panels (610x610, 305x610, 305x306) | 3-120 | |

| LKBB | Banana | LKBB2448 | 1 | 11.52 | Panels (610x610, 305x610, 305x307) | 3-120 | |

| LKBB | Banana | LKBB2461 | 1 | 14.64 | Panels (610x610, 305x610, 305x308) | 3-120 | 2 x 15 |

| LKBB | Banana | LKBB3061 | 1 | 18.3 | Panels (610x610, 305x610, 305x309) | 3-120 | |

| LKBB | Banana | LKBB3073 | 1 | 21.9 | Panels (610x610, 305x610, 305x310) | 3-120 | 2 x 22,5 |

| LKBB | Banana | LKBB3673 | 1 | 26.28 | Panels (610x610, 305x610, 305x311) | 3-120 | 2 x 22,5 |

| LKBB | Banana | LKBB3685 | 1 | 30.6 | Panels (610x610, 305x610, 305x312) | 3-120 | |

| LKBB | Banana | LKBB4373 | 1 | 30.66 | Panels (610x610, 305x610, 305x313) | 3-120 | 1×55 |

| LKBB | Banana | LKBB4385 | 1 | 36.55 | Panels (610x610, 305x610, 305x314) | 3-120 | 2 x 22,5 |

| LKBB | Banana | 2LKBB1861 | 2 | 10.98 | Panels (610x610, 305x610, 305x315) | 3-120 | |

| LKBB | Banana | 2LKBB2448 | 2 | 11.52 | Panels (610x610, 305x610, 305x316) | 3-120 | |

| LKBB | Banana | 2LKBB2461 | 2 | 29.28 | Panels (610x610, 305x610, 305x317) | 3-120 | 2 x 22,5 |

| LKBB | Banana | 2LKBB3061 | 2 | 36.6 | Panels (610x610, 305x610, 305x318) | 3-120 | 2 x 22,5 |

| LKBB | Banana | 2LKBB3073 | 2 | 43.8 | Panels (610x610, 305x610, 305x319) | 3-120 | 2 x 22,5 |

| LKBB | Banana | 2LKBB3661 | 2 | 43.92 | Panels (610x610, 305x610, 305x320) | 3-120 | 2 x 22,5 |

| LKBB | Banana | 2LKBB3673 | 2 | 52.56 | Panels (610x610, 305x610, 305x321) | 3-120 | 2 x 22,5 |

| LKBB | Banana | 2LKBB4373 | 2 | 61.32 | Panels (610x610, 305x610, 305x322) | 3-120 | 1×90 |

| LKBB | Banana | 2LKBB4385 | 2 | 73.1 | Panels (610x610, 305x610, 305x323) | 3-120 | 3 x 30 |

| LKBB | Banana | 2LKBB4396 | 2 | 82.56 | Panels (610x610, 305x610, 305x324) | 3-120 | 3 x 30 |

| LKBB | Banana | 3LKBB3673 | 3 | 78.84 | Panels (610x610, 305x610, 305x305) | 3-120 | 3 x 30 |

Details

Customer Case

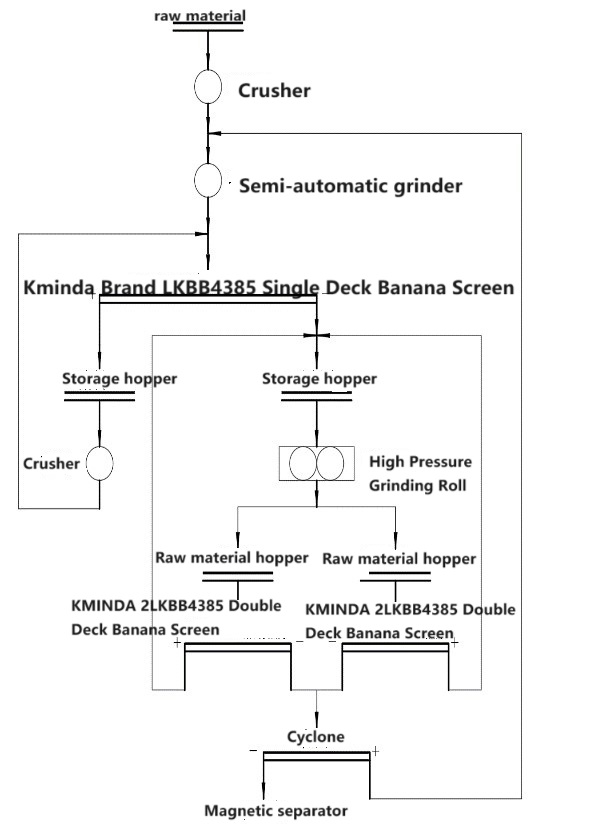

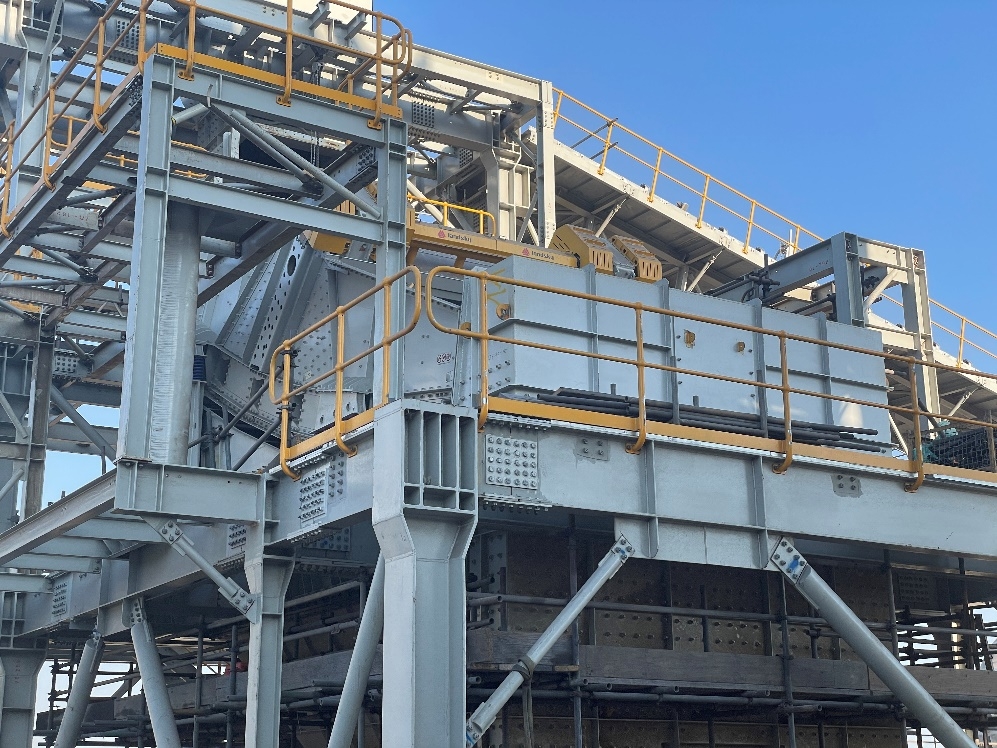

Model: LKBB4385/2LKBB4385 Process: Scalping/HPGR product screening Aperture: 45mm for scalping screen

SINO iron Ore Project is the largest magnetite project invested by China in Australia. In HPGR Improvement Project, single deck LKBB4385 banana screens are used as scalping screen before the HPGR, while double decks 2LKBB4385 banana screen are used as HPGR product screen. |  |

|  |

Service

KMD Banana screen is a custom solution

Our banana vibrating screens fully cover existing international specifications and can vary according to your current factory layout and handling capacity

Each application site has specific requirements - To ensure that the screen machine is exactly right for your specific field application and reduce the risk of maintenance requirements or failures, each of our screens can be specially customized to optimize existing processes or match parameters for new projects

Don't compromise on the original size, create a unique screen for your site and team.