close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

Introduction

KMD High Frequency Multi Deck Layer Stack Vibrating fine Screen is arranged in staggered layer from top to bottom. That is to integrate multiple screen boxes on a screen machine. Each screen box completes the feeding and screening operation independently, the undersize material and on oversize material of each screen box is collected and discharged separately, this special design can reduce footprint while ensuring processing capacity. According to the size of processing capacity, 1-5 layers of screen boxes can be selected. The most common is 5 layers of screen boxes stacked on one screen machine, also known as a High Frequency fine sizer.

1.This series of screen is applied double degree of freedom resonance principle and designed to utilize a single vibrating resource(vibrating motors) to drive whole screen to generate composite-vibration composed of linear vibration of screen box and mesh vibration stricken by vibrating rod row.

2.Vibration parameters can be controlled through frequency conversion, besides intermittent-instant-strong-vibration parameters can also be set to keep a non-blinding screening.

Multi deck sizer Feature and Advantage

2.1. fine particle screening efficiency can reach more than 90%.

The use of multi-layer screen box superimposed structural design, greatly improve the screening area of a single vibrating screen, equivalent to many ordinary screen machine at the same time, screening efficiency and processing capacity greatly improved.

2.2.The average service life of polyurethane wear-resistant screen panel is more than 6 months

High frequency multi deck screen adopts polyurethane panels. Our polyurethane wear-resistant panels have good quality, high opening rate, un-blocking design and high-wearing feature. High frequency multi deck screen also uses a special flow-divider and overflow feed box for feeding. The material is evenly distributed on the screen surface, and the overflow feed can also reduce the impact of the screen surface caused by too fast pulp flow rate, increase the service life of the polyurethane wear-resistant panel, making the average life of the polyurethane wear-resistant panel in more than 6 months.

2.3. Long service life of the whole Multi Deck Stack Vibrating Screen

Vibration motor: using American Martin motor, low energy consumption, high efficiency, stable performance.

Screen box: all parts of the screen box are lined with high wear-resistant rubber layer, combined with the surface of the box, high strength, never fall off, effectively avoid the wear of pulp on the screen box. The outer screen box adopts polyurethane spraying process, spraying thickness up to 2-3mm, greatly improving the screen box wear resistance and corrosion resistance. Screen box plate adopts high strength structural steel, laser cutting process. The overall heat treatment of the screen box eliminates stress, avoids secondary deformation of the screen box and effectively extends the service life of the equipment.

Multi layer screen production process

Laser cutting

Bending

Robot Welding

Sandblasting

PU Coating

Testing

Delivery

Details

|  |

Multi deck fine screen listing

| Landsky Model | Decks (Stank) | Length (mm) | Width (mm) | Working Area (Screening) | Power (kW) | Mesh Type (mm) | Aperture Range (mm) | Aprox. Weight (kg) |

| D1Z1014 | 1 | 1.4 | 1.0 | 1.4 | 2 X 0.55 | Flexible (1045x700) | 0.053-4.2 | 2,020.00 |

| D1Z1021 | 1 | 2.1 | 1.0 | 2.1 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 3,100.00 |

| D2Z1014 | 2 | 1.4 | 1.0 | 2.8 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 3,216.00 |

| D2Z1021 | 2 | 2.1 | 1.0 | 4.2 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 5,014.00 |

| D3Z1014 | 3 | 1.4 | 1.0 | 4.2 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 3,841.00 |

| D3Z1021 | 3 | 2.1 | 1.0 | 6.3 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 6,250.00 |

| D4Z1014 | 4 | 1.4 | 1.0 | 5.6 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 4,664.00 |

| D4Z1021 | 4 | 2.1 | 1.0 | 8.4 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 7,695.00 |

| D5Z1014 | 5 | 1.4 | 1.0 | 7 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 5,496.25 |

| D5Z1021 | 5 | 2.1 | 1.0 | 10.5 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 6,000.00 |

| D8Z1021 | 8 | 2.1 | 1.0 | 16.8 | 2 x 3.4 | Flexible (1045x700) | 0.053-4.2 | 13,038.00 |

| D1Z1014 | 1 | 1.4 | 1.0 | 1.4 | 2 X 0.55 | Flexible (1045x700) | 0.053-4.2 | 2,020.00 |

| D1Z1021 | 1 | 2.1 | 1.0 | 2.1 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 3,100.00 |

| D2Z1014 | 2 | 1.4 | 1.0 | 2.8 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 3,216.00 |

| D2Z1021 | 2 | 2.1 | 1.0 | 4.2 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 5,014.00 |

| D3Z1014 | 3 | 1.4 | 1.0 | 4.2 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 3,841.00 |

| D3Z1021 | 3 | 2.1 | 1.0 | 6.3 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 6,250.00 |

| D4Z1014 | 4 | 1.4 | 1.0 | 5.6 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 4,664.00 |

| D4Z1021 | 4 | 2.1 | 1.0 | 8.4 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 7,695.00 |

| D5Z1014 | 5 | 1.4 | 1.0 | 7 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 5,496.25 |

| D5Z1021 | 5 | 2.1 | 1.0 | 10.5 | 2 x 2.2 | Flexible (1045x700) | 0.053-4.2 | 6,000.00 |

| D6Z1021 | 6 | 2.1 | 1.0 | 12.6 | 2 x 3.4 | Flexible (1045x700) | 0.053-4.2 | 10,700.00 |

| D7Z1021 | 7 | 2.1 | 1.0 | 14.7 | 2 x 3.4 | Flexible (1045x700) | 0.053-4.2 | 11,756.00 |

| D8Z1014 | 8 | 1.4 | 1.0 | 11.2 | 2 x 3.4 | Flexible (1045x700) | 0.053-4.2 | 9,568.00 |

| D8Z1021 | 8 | 2.1 | 1.0 | 16.8 | 2 x 3.4 | Flexible (1045x700) | 0.053-4.2 | 13,038.00 |

| D5Z1216 | 5 | 1.6 | 1.2 | 9.6 | 2 x2.2 | Flexible (1245x840) | 0.053-4.2 | |

| D5Z1224 | 5 | 2.4 | 1.2 | 14.4 | 2 x 2.2 | Flexible (1245x840) | 0.053-4.2 |

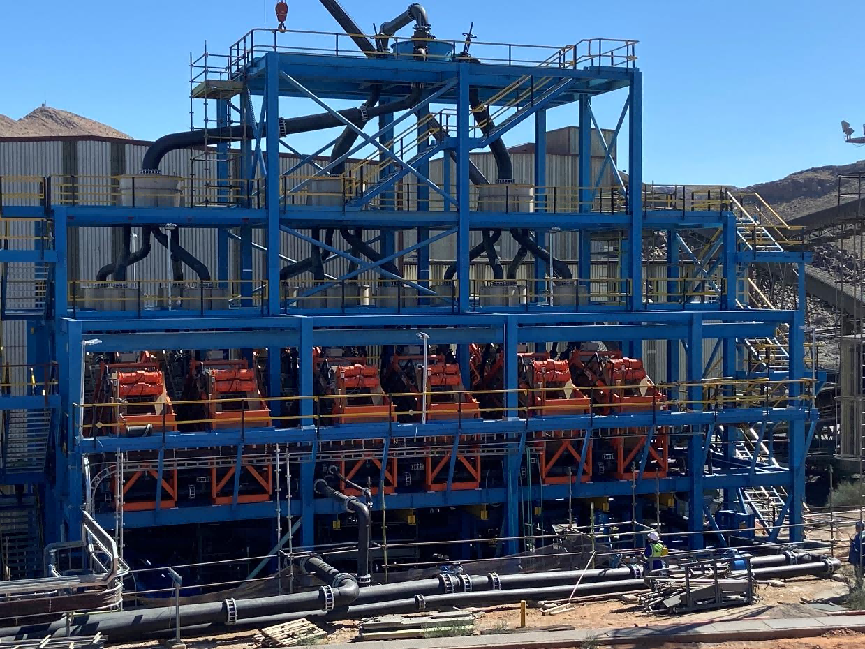

Customer case

Black Mountain Mine, Vedenta Ore Type: Zinc & Lead Model: D5FG1021 Quantity: 12 Cut Size: 0.125mm Process: Screen feed from mixture of rod mill and ball mill, undersize reports to flotation while oversize reports back to ball mill. |  |

Bakubang Platinum Mining Ore Type: Platinum Model: D5FG1021 Quantity: 4 Cut Size: 0.1mm Process: Screen feed from ball mill, undersize reports to flotation while oversize is the final tailing. |  |

Application

Mainly used in mineral processing, coal preparation, non-ferrous, non-metallic and other industries of fine material wet screening, grading operations.

We have a wide range of products and can provide various types of vibrating screens.

8.1) Circular vibrating screen

8.2) Repulp wet sizing screen

8.3) Dewatering screen

8.4) Electromagnetic screen

8.5) Composite vibrating screen

8.6) Scalping screen

8.7) Banana screen / Equal thickness vbrating screen

8.8) Linear vibration screen

8.9) Flip flow screen

8.10) Cyclone

8.11) Flexible polyurethane screen mesh / rubber panel / stainless mesh