close

Choose Your Site

Global

Social Media

Introduction

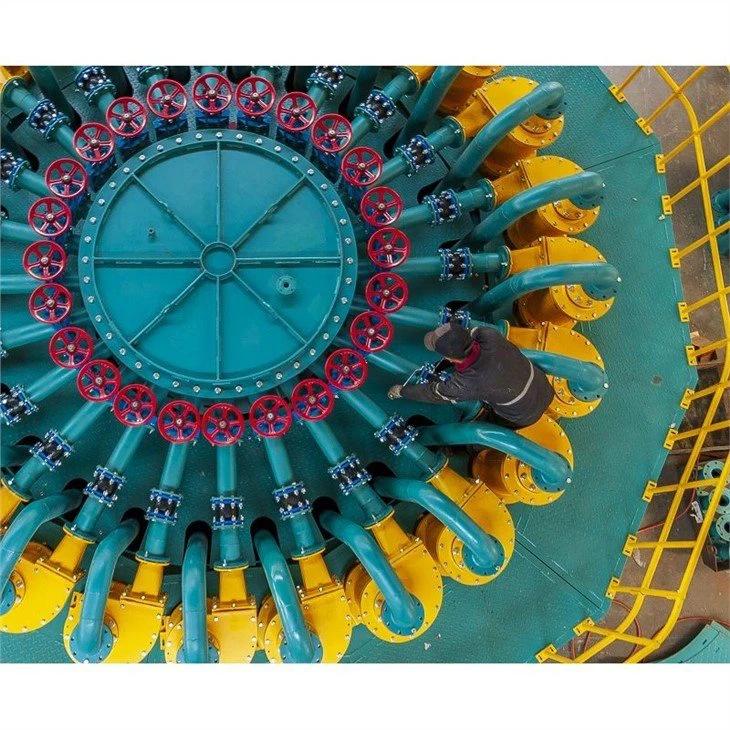

The working principle of cyclone is mainly centrifugal sedimentation. When the two-phase (or three-phase) mixture to be separated enters the cyclone at a certain pressure from the feed port of the cyclone, the strong three-dimensional elliptic turbulence of strong rotary shear will be generated. Due to the different density of particles, the centrifugal force, centripetal buoyancy, fluid drag force and other sizes are different, by centrifugal sedimentation, most of the coarse particles (or heavy phase) discharged through the cyclone bottom port, and most of the fine particles (or light phase) discharged by the overflow pipe, so as to achieve the purpose of separation and classification. The structure design of our cyclone is unique, which adopts multi-section column compound structure. Polyurethane Hydrocyclone the column height can be increased or decreased according to the needs. If the height is increased, the overflow fineness can be increased to about 10μm. And each diameter has a unique combination of cylinder length and cone Angle, which can achieve the maximum tangent velocity under the minimum total cyclone length, so as to increase the centrifugal force of materials and improve cyclone the classification efficiency.

The Polyurethane Cyclone is a classification device that uses centrifugal force to accelerate the settlement of ore particles, therefore, the power consumption is small. The advantage is that it takes small space with large treatment quantity and high classification efficiency. A very fine overflow product can be obtained, thus it is very cost-effective.

| Model | Lining Material | Diameter (mm) | Feeding Pressure(MPa) | Aperture range(μm) | Capacity(m³/h) |

| LKX-100 | Rubber | 100 | 0.10-0.30 | 20-50 | 6-25 |

| LKX-150 | Rubber | 150 | 0.08-0.30 | 20-74 | 14-40 |

| LKX-200 | Rubber | 200 | 0.06-0.30 | 40-100 | 25-60 |

| LKX-250 | Rubber/Ceramic | 250 | 0.06-0.30 | 40-100 | 40-100 |

| LKX-300 | Rubber/Ceramic | 300 | 0.06-0.20 | 50-150 | 45-100 |

| LKX-350 | Rubber/Ceramic | 350 | 0.06-0.20 | 50-150 | 70-160 |

| LKX-400 | Rubber/Ceramic | 400 | 0.06-0.20 | 74-150 | 100-220 |

| LKX-500 | Rubber/Ceramic | 500 | 0.04-0.20 | 74-200 | 140-300 |

| LKX-610 | Rubber/Ceramic | 610 | 0.04-0.15 | 74-200 | 200-300 |

| LKX-660 | Rubber/Ceramic | 660 | 0.04-0.15 | 74-220 | 260-500 |

| Model | Lining Material | Diameter (mm) | Feeding Pressure(MPa) | Aperture range(μm) | Capacity(m³/h) |

| LKX-50-PU | Polyurethane | 50 | 0.10-0.40 | 5-40 | 2-5 |

| LKX-100-PU | Polyurethane | 100 | 0.10-0.30 | 20-50 | 6-25 |

| LKX-150-PU | Polyurethane | 150 | 0.08-0.30 | 20-74 | 14-40 |

| LKX-200-PU | Polyurethane | 200 | 0.06-0.30 | 40-100 | 25-60 |

| LKX-250-PU | Polyurethane | 250 | 0.06-0.30 | 40-100 | 40-100 |

| LKX-300-PU | Polyurethane | 300 | 0.06-0.20 | 50-150 | 45-100 |

| LKX-350-PU | Polyurethane | 350 | 0.06-0.20 | 50-150 | 70-160 |

| LKX-400-PU | Polyurethane | 400 | 0.06-0.20 | 74-150 | 100-220 |

| LKX-500-PU | Polyurethane | 500 | 0.04-0.20 | 74-200 | 140-300 |

Feature and Advantage

1. The liner materials inside cyclone can be high alumina ceramics, wear-resisting rubber and polyurethane, and meet customers' individual requirement for wear and corrosion resistance.

2. In metal mining industries, cyclones are applied in primary or secondary closed-circuit grinding or open-circuit grinding or open-circuit classification. It's easy to adjust parameters of overflow particle sizes, underflow concentration and circulating load, and liable to satisfy production management on site.

DEWATERING SYSTEM

Dewatering System consists of Hydrocyclone and LKLM Linear Screen with good dewatering performance, small floor area and low investment & operation costs. It is of great significance in improving the comprehensive utilization efficiency of resources and promoting the construction of a green and environmentally friendly mining system.

|  |

|  |

Application

It is often used for material classification and separation of coarse particles such as it is normally used in the second section of closed circuit grinding as a classification equipment.

|  |

Others related products

5.1) Circular vibrating screen

5.2) Repulp wet sizing screen

5.3) Dewatering screen

5.4) Electromagnetic screen

5.5) Composite vibrating screen

5.6) Scalping screen

5.7) Banana screen / Equal thickness vbrating screen

5.8) Linear vibration screen

5.9) Flip flow screen

5.10) Cyclone

5.11) Flexible polyurethane screen mesh / rubber panel / stainless mesh