close

Choose Your Site

Global

Social Media

Stainless steel welding screen is a fine metal mesh structure element used for screening and filtration. Widely used in many industries in screening, dehydration, filtration and other reference, with high strength, stiffness and carrying capacity, can be made into a variety of shapes of rigid screening filter device.

About basic structure,wedge-shaped cross section screen bars are arranged according to the prescribed screen joints, and welded together with the support bars of wedge-shaped or rectangular and circular cross sections to form a wedge-shaped slit screen mesh. The basic structure is shown in Figure 1.

Figure 1 Basic structure of welding screen

See Table 1 for section shape and size specifications of screen and support strip:

Table 1 Section shape and size of screen and support strip

Product Features:

1. no blocking: V-shaped screen to form a wedge gap to ensure that not blocked;

2. high precision screen seam: automatic welding to ensure the accuracy of the screen seam;

3. easy to clean: the surface can be removed with a scraper or backblow;

4. strong machinability: can be made into a variety of shapes of rigid screening filter device;

5. high mechanical properties;

6. long life using;

7. low maintenance costs.

Application

It can be processed into vibrating screen plate, dewatering centrifuge sieve basket, arc screen, cylindrical sieve barrel, filter element, well engineering filter pipe and other components, widely used in petroleum, chemical industry, chemical fiber, salt making, pharmaceutical, light industry papermaking, well engineering, metallurgy, coal washing, building materials, cement, ceramics, glass, food, water treatment and other industries.

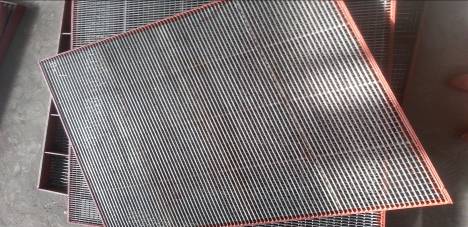

Figure 2 Vibrating Screen Plate

Figure 3 Screening Plate of Jig

FIG. 4 Centrifuge sieve basket

Figure 5 Curved screen plate

Figure 6 The sieve barrel of the cylindrical sieve

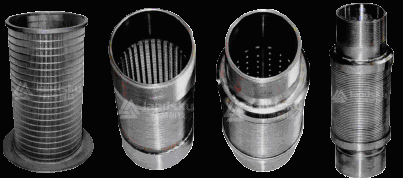

Figure 7 Various filter tubes

Figure 8 Various filter elements

FIG. 9 Filter pipe for well engineering

content is empty!